-

Home

-

Products

-

About Us

-

News

-

Contact Us

Leave Your Message

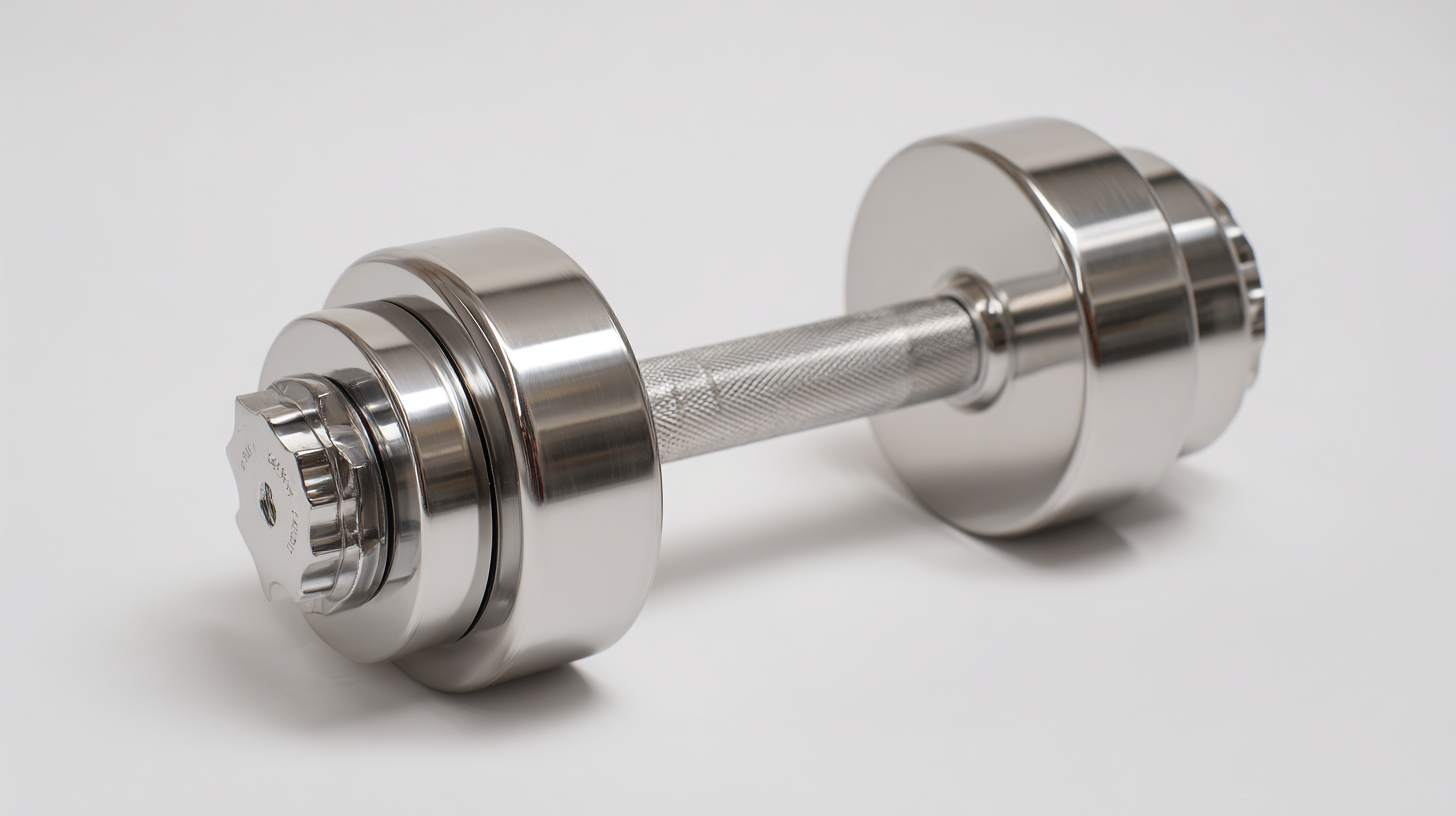

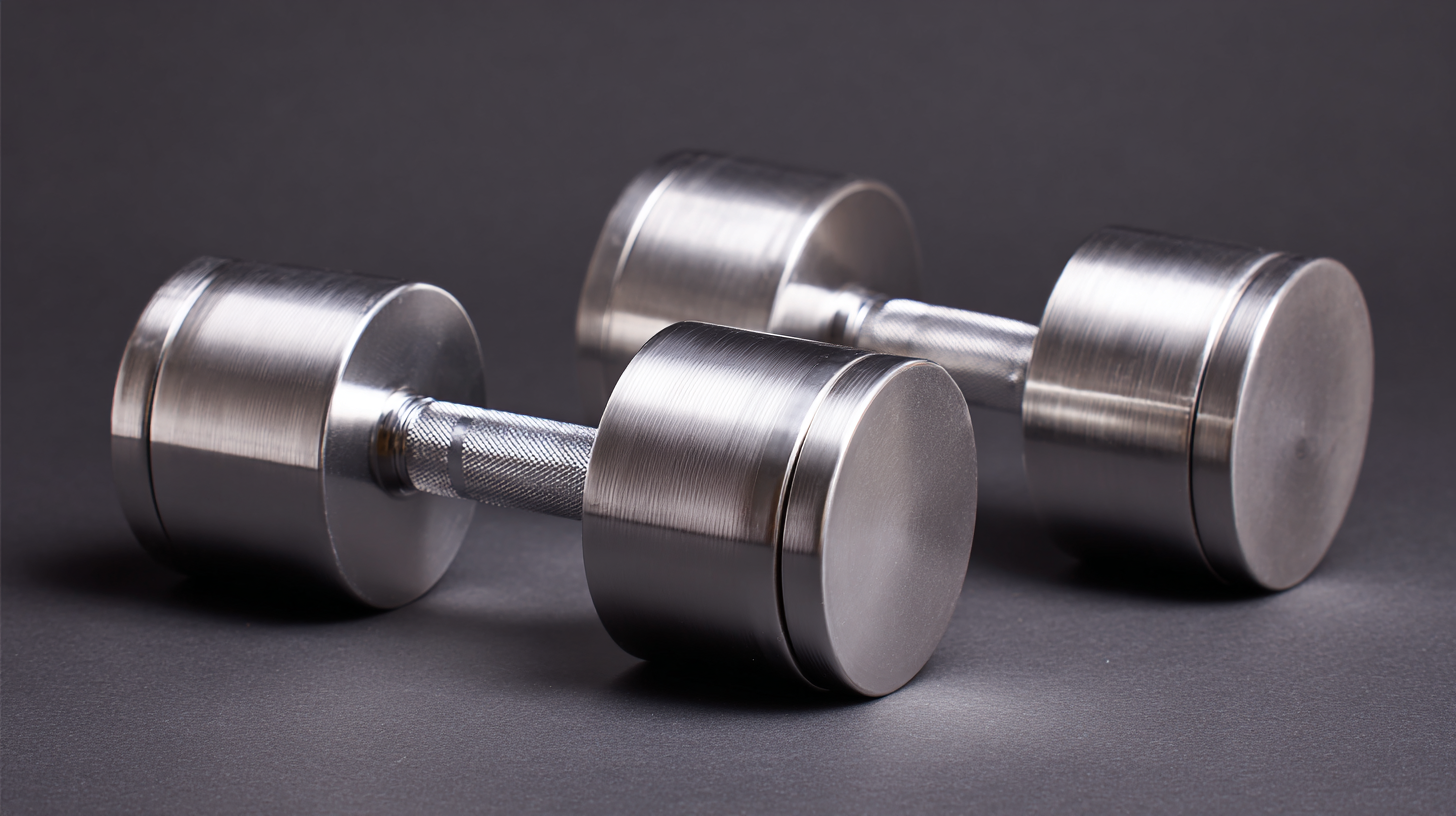

When it comes to outfitting a gym or home workout space, the choice of fitness equipment can significantly influence both performance and results. Among the plethora of options available, Stainless Steel Dumbbells have gained substantial popularity due to their durability, aesthetic appeal, and resistance to rust and corrosion. According to a report by Grand View Research, the global fitness equipment market is projected to reach USD 15.2 billion by 2028, with a notable demand for high-quality materials like stainless steel driving this growth. As more consumers recognize the importance of investing in reliable workout tools that withstand the test of time, selecting the right manufacturer becomes crucial. This guide aims to provide insights into how to choose the best stainless steel dumbbell manufacturer, ensuring that you benefit from superior craftsmanship and longevity in your fitness journey.

When choosing stainless steel dumbbells, identifying key attributes that contribute to their quality and durability is crucial. First and foremost, the grade of stainless steel used is paramount. High-quality dumbbells are often made from 316 or 304 stainless steel, which ensures resistance to rust and corrosion. This is particularly important for those who may sweat during workouts or use the dumbbells in humid environments. Additionally, the finish of the dumbbell plays a significant role in its overall quality; a polished surface not only enhances aesthetics but also makes cleaning easier, prolonging the life of the equipment.

Another essential attribute is the weight distribution and design of the dumbbells. Quality stainless steel dumbbells should have a solid construction that minimizes wobbling and ensures that the weight is evenly distributed. This stability is vital for safety and performance during various exercises. Moreover, ergonomic handles that offer a comfortable grip can greatly enhance user experience and reduce the risk of injuries. When considering a manufacturer, it's advisable to look for those that prioritize these features, ensuring that the dumbbells are not only durable but also user-friendly for a wide range of workouts.

| Attribute | Description | Importance Level | Typical Testing Method |

|---|---|---|---|

| Material Quality | Grade of stainless steel used, typically 304 or 316 grade. | High | Metal composition analysis |

| Weight Accuracy | Dumbbells should meet specified weight tolerances. | High | Calibration against a certified scale |

| Finish Quality | Surface finish to resist corrosion and provide grip. | Medium | Visual inspection and grip test |

| Handle Design | Ergonomic design for comfort and safety during use. | High | User feedback and ergonomic testing |

| Warranty Period | Duration of manufacturer's warranty for product defects. | Medium | Review warranty documentation |

When selecting a stainless steel dumbbell manufacturer, understanding the manufacturing process is crucial for ensuring optimal durability and quality. The process typically begins with the selection of high-grade stainless steel, as this material provides superior resistance to corrosion and wear. Manufacturers who prioritize quality will often source materials from reputable suppliers and perform rigorous testing to ensure that the steel meets industry standards. This foundational step sets the stage for producing durable and long-lasting dumbbells.

Once the materials are secured, the next step generally involves advanced forging techniques, which can significantly enhance the strength and resilience of the dumbbells. Forging creates a tighter grain structure in the metal, leading to improved mechanical properties compared to cast alternatives. Additionally, a manufacturer committed to quality will invest in precision machining and finishing processes. This includes ensuring that the surface is free from any imperfections, as a smooth finish not only enhances aesthetics but also contributes to the longevity of the product. By examining each stage of the manufacturing process, consumers can make informed decisions and choose a manufacturer that aligns with their requirements for durability and performance.

When selecting a stainless steel dumbbell manufacturer, evaluating certifications and industry standards is paramount to ensuring quality and durability. A reputable manufacturer should adhere to recognized certifications such as ISO 9001, which signifies a commitment to quality management systems. According to a 2022 report from the International Organization for Standardization, companies that implement ISO standards often see productivity improvements of up to 30%. This emphasizes that certified manufacturers prioritize not only the quality of their products but also continuous improvement in their production processes.

Additionally, compliance with industry standards like ASTM (American Society for Testing and Materials) or EN (European Norms) can provide insights into the performance and safety of dumbbells. For instance, the ASTM F2270 standard evaluates the mechanical performance of weight training equipment, ensuring that the materials used can withstand the rigors of heavy lifting over time. Research indicates that manufacturers following these standards report a significantly lower return rate of defective products, translating to increased customer satisfaction and trust. When choosing a supplier, it’s essential to verify these certifications and standards to ensure that you are investing in durable and high-quality fitness equipment.

When selecting a stainless steel dumbbell manufacturer, price is often the first consideration, but several other factors should play a crucial role in your decision-making process. Quality of materials is paramount; a reputable manufacturer uses high-grade stainless steel that not only resists corrosion but also withstands the wear and tear of regular use. Look for brands that provide detailed specifications about their materials and manufacturing processes, as transparency is often a sign of quality assurance.

Another important factor is the manufacturer's production capabilities and quality control measures. It’s essential to choose a company that has a robust quality management system in place. This ensures that every product they produce meets high standards for consistency and durability. Additionally, researching customer feedback and testimonials can provide insights into the long-term performance of the dumbbells you’re considering. A manufacturer known for excellent after-sales service and warranty policies can also offer peace of mind, as this shows they stand behind their products and are committed to customer satisfaction.

When selecting a stainless steel dumbbell manufacturer, customer reviews and feedback play a crucial role in guiding your decision. These insights provide a real-world perspective on the quality and durability of the products. Positive reviews often reflect a manufacturer's commitment to excellence, indicating that they understand the needs of their customers and deliver reliable goods. Reading about other users' experiences can highlight specific features or advantages that might not be evident in product descriptions alone.

When selecting a stainless steel dumbbell manufacturer, customer reviews and feedback play a crucial role in guiding your decision. These insights provide a real-world perspective on the quality and durability of the products. Positive reviews often reflect a manufacturer's commitment to excellence, indicating that they understand the needs of their customers and deliver reliable goods. Reading about other users' experiences can highlight specific features or advantages that might not be evident in product descriptions alone.

Additionally, negative feedback can be equally informative. If multiple reviews cite similar issues—be it regarding the craftsmanship, materials used, or customer service—it can serve as a red flag. Manufacturers who prioritize customer service and product quality will often address concerns noted in reviews promptly, demonstrating their willingness to improve. By paying attention to overall ratings and detailed comments, you can better assess which manufacturer aligns with your standards for quality and durability, ensuring your investment in dumbbells supports your fitness journey effectively.